Key Responsibilities of a Fabricator

Responsibilities Defined: Navigating the Fabricator's Terrain

The role of a fabricator is crucial in the manufacturing and metal fabrication industries. As part of a collaborative team, fabricators are entrusted with the task of transforming blueprints and technical drawings into tangible, finished products. While the job description may vary slightly across organizations, there are key responsibilities that every fabricator is expected to fulfill.

First and foremost, fabricators are tasked with reading and interpreting technical drawings and blueprints, a critical skill that requires attention to detail. This ensures that all specifications are adhered to and the quality of the work meets industry standards. Fabricators must possess the ability to utilize various tools and machinery to cut, bend, and assemble metal parts efficiently.

Welding is a significant aspect of a fabricator's job. Whether working with structural metal or delicate components, a welding fabricator needs to deliver precise and strong welds. This skill is often honed through on-the-job training and development, as practical experience plays a vital role.

Quality control is another important responsibility. Fabricators must ensure that all fabricated parts meet the required quality standards before they are assembled into the final product. This often involves inspecting and testing various metal structures and tools to confirm their suitability.

To thrive in this role, a high school diploma is typically required as a basic educational qualification. However, specific training or a description template detailing specialized skills in welding, metal fabrication, or operating tools can enhance a fabricator's credentials. For those considering entering this field, it's worth exploring the potential job structures available and how they might fit your lifestyle and career goals.

Ultimately, the responsibilities of a fabricator extend beyond manual labor. Their work contributes to producing high-quality products, and they must work closely with other team members to ensure seamless operations within the manufacturing setting.

Essential Skills for a Successful Fabricator

Mastering the Art of Metalwork

In the world of metal fabrication, fabricators play a pivotal role in transforming raw materials into finished products. To excel in a fabricator job, one needs a blend of technical expertise and practical skills. At the forefront is the ability to read and interpret technical drawings and blueprints. This skill allows fabricators to understand the intricate details required to shape metal components and ensure everything aligns with the project specifications. A fabricator's job description often highlights proficiency in using tools and machinery as essential. Whether crafting structural metal or smaller metal parts, fabricators must handle a variety of fabrication tools with precision. Welding, for example, is a fundamental aspect of metalwork that demands both skill and safety awareness. Furthermore, attention to detail is critical for producing high-quality products. Fabricators must accurately measure, cut, and assemble parts to guarantee the finished products meet industry standards. Teamwork is also a crucial skill, as fabricators frequently collaborate with engineers and other team members to achieve project goals. A high school diploma is typically the minimum educational requirement, but additional training on specific tools, safety protocols, and advanced welding techniques can greatly enhance a fabricator's career prospects. Training and development initiatives are essential for keeping pace with changes in the manufacturing industry and improving one's fabricator responsibilities. If you're interested in part-time work hours in California, consider exploring the available opportunities in metal fabrication roles. Understanding the dynamics of part-time employment can offer flexibility in this demanding field. While the core skills for a successful fabricator remain consistent, the ever-evolving landscape of metal fabrication requires professionals to continually update their skill sets. This ensures they remain competitive and capable of crafting high-quality components and products in an industry that thrives on precision and innovation.Challenges in Hiring Fabricators

Challenges in the Hiring Process

Hiring a qualified fabricator can be a daunting task for many companies, especially given the vast array of skills and responsibilities outlined in a fabricator job description. Understanding and identifying the necessary aptitudes for metal fabrication is crucial, yet some hurdles persist.

Firstly, the specialized nature of the metal fabricator role requires candidates to not only master a variety of tools and machinery but also to possess the ability to read and interpret technical drawings and blueprints. This is crucial in producing quality metal parts and components.

Furthermore, the competition is tough. As more industries rely on precision metal structures and finished products, the demand for skilled fabricators grows. As a result, employers often face challenges in attracting top-tier talent.

Here's a closer look at some of the hurdles encountered:

- Scarcity of Qualified Candidates: Individuals with the training and experience necessary to successfully carry out the responsibilities of fabricators are in high demand.

- Training and Skill Assessment: Evaluating a fabricator's skills involves practical assessments that are both time-consuming and resource-intensive.

- Compensation Expectations: To secure skilled professionals, companies must ensure competitive pay and benefits, which can strain budgets.

- Cultural and Team Fit: Beyond technical expertise, fabricators must work well in a team environment, highlighting the importance of finding a suitable cultural fit.

Ultimately, overcoming these challenges demands a strategic approach that balances technical requirements with recruitment efforts focused on a collaborative team environment. For further insights on hiring strategies, you can explore the concept of temp-to-hire employment.

Evaluating Fabricator Candidates

Assessing Technical Proficiency

When evaluating fabricator candidates, it's crucial to assess their technical proficiency. This includes their ability to read and interpret technical drawings and blueprints, which are fundamental in the fabrication process. Candidates should demonstrate a strong understanding of metal fabrication techniques and the ability to use tools and machinery effectively. Their experience with welding and assembling metal parts into finished products is also a key indicator of their capability.

Attention to Detail and Quality Assurance

Attention to detail is a critical skill for fabricators, as it directly impacts the quality of the products they produce. During the hiring process, consider how candidates ensure precision in their work and maintain high standards of quality. This involves checking their familiarity with quality control processes and their ability to identify and rectify defects in metal structures.

Evaluating Problem-Solving Skills

Fabricators often face challenges that require quick thinking and problem-solving skills. Assessing a candidate's ability to troubleshoot issues during the manufacturing process is essential. Look for examples of how they have overcome obstacles in previous roles, particularly in situations involving complex components or structural metal work.

Team Collaboration and Communication

While technical skills are vital, the ability to work well within a team is equally important. Fabricators frequently collaborate with other team members to complete projects efficiently. Evaluate candidates on their communication skills and their ability to work collaboratively in a team environment. This includes understanding their role within the team and how they contribute to achieving common goals.

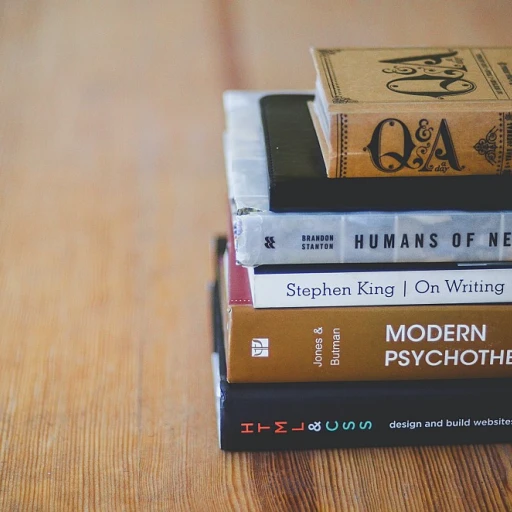

Education and Training Background

A high school diploma is often a minimum requirement for fabricator roles, but additional training can set candidates apart. Consider their educational background and any specialized training or certifications they may have in metal fabrication or welding. Continuous learning and development are important, as discussed in the training and development section, to keep up with industry advancements.

Training and Development for Fabricators

Investing in Skill Development for Metal Fabricators

The success of a fabricator is deeply tied to their skills and ability to work accurately with metal parts. Investing in training and development programs ensures that fabricators can interpret technical drawings and blueprints effectively. This skill is critical in manufacturing quality products and components, a responsibility that falls squarely on fabricators. High school diploma holders interested in fabrication may require guidance on using tools and machinery pertinent to the industry. This guidance can take the form of on-the-job training, mentorship programs, or dedicated courses that cover components of the job description. Training should emphasize:- Reading and Interpreting Blueprints: Understanding these is crucial for creating structural metal forms and ensuring the fabricated parts meet the necessary standards.

- Welding Techniques: As welding is a significant aspect of the fabricator role, mastery of various techniques supports consistency in finished products.

- Use of Tools and Machinery: Familiarity with tools like saws, drills, and other fabrication equipment is essential for efficient work.

Future Trends in Fabrication Jobs

Emerging Trends Shaping the Future of the Fabrication Industry

The fabrication industry is constantly evolving, driven by technological advancements and shifts in market demands. Understanding these trends allows metal fabricators to adapt and thrive in a competitive landscape. Here are some key trends shaping the future of fabrication jobs:- Automation and Robotics: The incorporation of automation, such as robotic welding and CNC machinery, is transforming the way metal fabrication work is done. Automating repetitive tasks enhances efficiency and allows fabricators to focus on more complex projects, ultimately improving the quality of finished products.

- Sustainability and Eco-friendly Practices: There's a growing emphasis on environmentally sustainable fabrication practices. Fabricators are increasingly adopting green technologies and materials to reduce waste and energy consumption, aligning with industry trends towards sustainability.

- Advanced Materials and Techniques: Innovations in materials, such as lightweight composites and advanced alloys, are broadening the scope of metal fabrication. Understanding and mastering these materials requires ongoing training and development, enhancing the fabricator's role in production.

- Integration of Digital Fabrication Technologies: The rise of digital tools, including CAD software and 3D printing, is revolutionizing how fabricators approach the design and manufacturing of components. These tools assist in accurately reading and interpreting technical drawings and blueprints, streamlining the fabrication process.

- Increased Collaboration and Teamwork: As the fabrication industry becomes more specialized, collaboration among team members with diverse skills (welding, designing, quality control) becomes crucial. Working effectively in teams enhances the overall efficiency and quality of the fabrication work being produced.

- Emphasis on Training and Skill Development: Continuous learning is essential in adapting to technological advancements. Fabricators must engage in regular training sessions to hone their skills, such as operating new tools and machinery, and understanding the latest industry trends.